14-18 KENT STREET EAST: THE OLD MILL

T

THE BEGINNING

A common misconception heard throughout Kawartha Lakes is that the current mill ruins were built and managed by William Purdy, often colloquially known as “Purdy’s Mill.” Although the current mill is located on the original Purdy Tract, his mill was located up the river where a dam was built as well.

After Purdy was imprisoned briefly on charges of sympathizing with Mackenzie’s Rebellion in 1837, he and one of his sons left Lindsay entrusting his son Hazard to manage the mill operations. After the property changed hands from the Purdy family to the Bigelows, Lindsay’s first mill was a victim of the fire that swept and destroyed much of the town’s business core in 1861.

Enter the Needlers

The ruined mill site was purchased by Walker Needler in 1862 shortly after arriving to town. Constructed in 1869, the new stone grist and lumber mill was given to his son, William Walker Needler, and his son-in-law, Thomas Sadler. This partnership lasted until the week of August 10, 1884, when Needler retired; selling his shares in the business to Joseph Rutherford Dundas.

Sadler, Dundas & Flavelle Milling Co. - 1892

Needler & Sadler

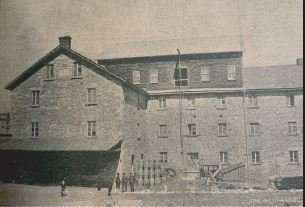

After the site was destroyed by the fire of 1861, Walker Needler bought the land and began construction on the east wing of the mill. In 1867, Needler sold the mill to his son William Needler and Thomas Sadler. By 1869, the west wing was constructed and a new grist mill was in operation under the name of Needler & Sadler. The grinding capacity under their management was 175 barrels per day by 1884.

Sadler, Dundas & Flavelle Milling Co.

With the success of the newly constructed mill, the Flavelle Bros., along with Dundas, bought William Needler’s share in the company. Under Flavelle management, the mill was remodelled and modern equipment was purchased which increased grinding capacity to 1,000 barrels per day, achieved an annual lumber cut ov over one million feet, and had a fully functional 90,000 bushel elevator.

Operations: Starting in 1884, the mill underwent many operational changes and remodelling that saw the output of flour increase to 30,000 bushels of wheat per month. In addition to increasing its flour output, with J. D. Flavelle as the manager, a new grain elevator across the river was erected, grinding of rolled oats, pot barley, rolled wheat, a feed mill, and split peas commenced and expanded over the course of a ten year period. Aside from the flour trade, two departments with the mill are highlighted below:

Rolled Flake Oats: By 1896, the rolled flake oats business was one of Flavelle Milling Company’s largest departments beside flour production. Located on the second storey over the engine room was a large steam dry-kiln (150 barrel per day dry capacity) which was the beginning of the process for producing rolled oats. Taken in at the east entrance to the flour mill, the oats were cleansed and dried before being transferred to the sheller and then converted into flake oats, or standard and pin head meal. They are then barrelled and ready for shipment. This part of the business lasted until the mill’s closure in 1910.

Split Peas: After J. D. and William Flavelle bought 50 percent interest in the split pea business of Charles Squire, the Flavelle Milling Company began production of split peas in the mill. With a capacity of 125 barrels per day, the peas would first be taken at the east entrance on the ground floor where they would undergo cleaning before going through elevators to the dry kiln. Once dried, the peas would be run through a stone roller that would split the peas down the centre. Once split, they would be barrelled or sacked for export or purchasing by locals.

Each year the mill would increase its production and employment under the direct supervision of J. D. After the installation of model equipment and all processes implemented, the firm would see profits ranging between $16,000 and $30,000 each year. That would be roughly $425,000 and $800,000 in 2023 dollars!

Flavelle Milling Company Ltd.

By 1898, J. D. Flavelle bought out the remaining interest of his partners and continued production of his million dollar operation. Lumber cutting ceased production in 1900 and all remaining gristing interest was bought by the Canadian Cereal and Milling Co., in 1910; until shutting down a short time later in 1915.

THE LOCAL GRISTMILL

The Proprietors

-

William Needler

1833 - 1919

Owner until 1885

-

Joseph R. Dundas

1836 - 1896

Owner until 1896

-

William Flavelle

1853 - 1943

Owner until 1910

-

John D. Flavelle

1850 - 1925

Owner until 1911

Left to Right

Mill 1894

Flavelle 1904

Flavelle Elevator

J. D. Flavelle in his office

J. D. Flavelle front row center with employees

Flavelle employee parade

THE LOCAL DISTILLERY

Industrial Alcohol Works Ltd.

Once the Canadian Cereal Milling Co. ceased production in 1915, the mill laid vacant until 1926. Plans for a distillery were drawn up by Charles Millar and upon his death, Henry Pallett and others collected enough capital to secure those plans.

After obtaining the mill - which at the time was thought to be the perfect space for a distillery - and the machinery put in place, the Industrial Alcohol Works Ltd. officially opened on January 14 of 1927. When production began, the plant’s initial output was approximately 900,000 gallons annually. The Board of Directors hoped that with enough public investment, the capacity could be increased very quickly.

Lindsay Distilleries Limited

Within a short time, the Industrial Alcohol Works Ltd. formally changed its corporate name in 1927. The distillery on the Scugog would not last much longer in Lindsay. Unfortunately by 1930, the company faced multiple trademark infringement lawsuits as well as an eventual bankruptcy later the same year. Prohibition may have contributed to the distillery’s closure as well.

THE LOCAL HATCHERY

Henderson’s Chick Hatchery

The final business to occupy 14 Kent Street East was Henderson’s Chick Hatchery. Opened in 1941 by Gordon Henderson, this chick hatchery was one of three local hatcheries around Lindsay.

During its 30 year tenure on the Scugog River, the small business serviced Victoria County with quality chicks. The family lived on site in an attached single story residence next to the business to maintain the high quality service that their customers had grown to expect. Mr. Henderson lived there with his wife Gretta, where they raised their four children.

As innovation swept across the poultry industry in Ontario, Henderson hatched thousands of baby chicks every week which included an array of five-six different breeds of chicks, ranging from purebred Barred Plymouth Rocks and New Hampshires to hybrid breeds. Shipments to Montreal and Toronto by the thousands became frequent for this hatchery as they continued to grow year after year.

Guaranteeing 100 percent pullets for every 100 pullets, Henderson’s prices were competitive; ranging from $42.00-$53.00 per 100 depending on the breed that was ordered. Unlike today, where upwards of 20,000 chicks can be hatched in a single incubator, Henderson’s operated with 14 incubators that would hold roughly 2,700 eggs at a time. Under the supervision of Douglas Williams, in three months, over 85,000 eggs were hatched in this local business.

The Brooding Room

The second floor of Henderson’s Chick Hatchery was where eggs spent their final three days before hatching.

Once in a brooder, Gordon Henderson would check to ensure that every brooder was working and that a temperature of 100 degrees Fahrenheit was regulated until the eggs hatched. Once the eggs hatched on day 21, all brooders were cleaned and disinfected by either Gordon or Douglas.

Baby chicks would begin their life in this room. They continued to do so until they were bought by local farmers around Victoria County, or shipped out across the country.

Sharing the Space

In addition to being a hatchery, a portion of the building was rented out to Mr. Jamison, a local furniture finisher, as well as the offices of Master Feeds - storefront located adjacent. Gordon Henderson and Lloyd Burrows set up a boxing ring on the second floor where amateur community boxers could train.

By 1974, the hatchery was no longer in operation and Gordon Henderson sold the building to local entrepreneur, Enzo Gentile. On January 11, 1974, Enzo Gentile hoped that one day the space would be home to a hotel and restaurant after much renovation. The building sat vacant until 1978, when the mill burned to the remnants that remain today.

REMNANTS OF THE PAST

On June 21, 1978, the vacant building was set ablaze by three young boys. Within minutes, the entire 20,000 square foot former hatcher was fully engulfed in flames.

Firefighters battled the blaze for several hours with the fire threatening nearby buildings as heavy palls of smoke covered the entire vicinity: making it difficult for first responders to know where the blaze was.

To the credit of the firefighters, under the shower of sparks, they were able to contain the $100,000 fire to just the mill. The summer of 1978 started with a local landmark in ruins and its chapter in Lindsay’s history closed.

Today the ruins stand as an historical reminder of its former uses as a grist mill, a distillery, and a hatchery. A shell that tells the story of industries past and also of the people who worked so hard to build sustainable businesses to service a growing population throughout the 19th, 20th, and into the 21st centuries. Although it was hoped that the building would be restored and converted to a restaurant and hotel, it has instead been turned into a park for all residents to enjoy.